LABORATORY FOR MECHANICAL TESTS AND EXPRESS DIAGNOSTICS

SECTION FOR EXPRESS DIAGNOSTICS

PROJECT BG05M2OP001-1.001-0008 | NATIONAL CENTER OF MECHATRONICS AND CLEAN TECHNOLOGIES

Manager:Senior assist. prof. Vanya Dyakova, Ph.D. (IMSETHAC-BAS)

E-mail: v_diakova@ims.bas.bg

Phone. +359 887 224 276

The section performs analysis of the chemical composition, microstructure of metallic materials and fractography by optical emission spectrometry, X-ray microanalysis and scanning electron microscopy. Potential partners and clients of the laboratory may be research teams with similar research interests and organizations engaged in the study of metal products.

ACTIVITIES

- Chemical analysis of Fe, Al, Cu alloys.

- Qualitative and quantitative analysis of the macro- and microstructure of the materials.

- Determination of the local elemental composition at a point, along a line and by area in bulk samples, thin layers, coatings; establishment of macro- and microchemical inhomogeneity.

- Investigation of the macro- and micromorphology of working and destroyed surfaces. Fractographic analysis.

SERVICES

- Determination of the chemical composition of Fe, Al, Cu alloys.

- Qualitative and quantitative analysis of the macro- and microstructure structure of materials.

- Determination of the local elemental composition in point, line and area in massive samples, thin layers, coatings; establishment of macro- and microchemical inhomogeneity.

- Investigation of the macro- and micromorphology of working and destroyed surfaces. Fractographic analysis.

- Diagnosis of the condition of industrial facilities by on-site control of the microstructure.

- Metal-physical analysis of the relationship of composition and structure with the properties of materials.

- Expertise of operational damages and accidents.

EQUIPMENT

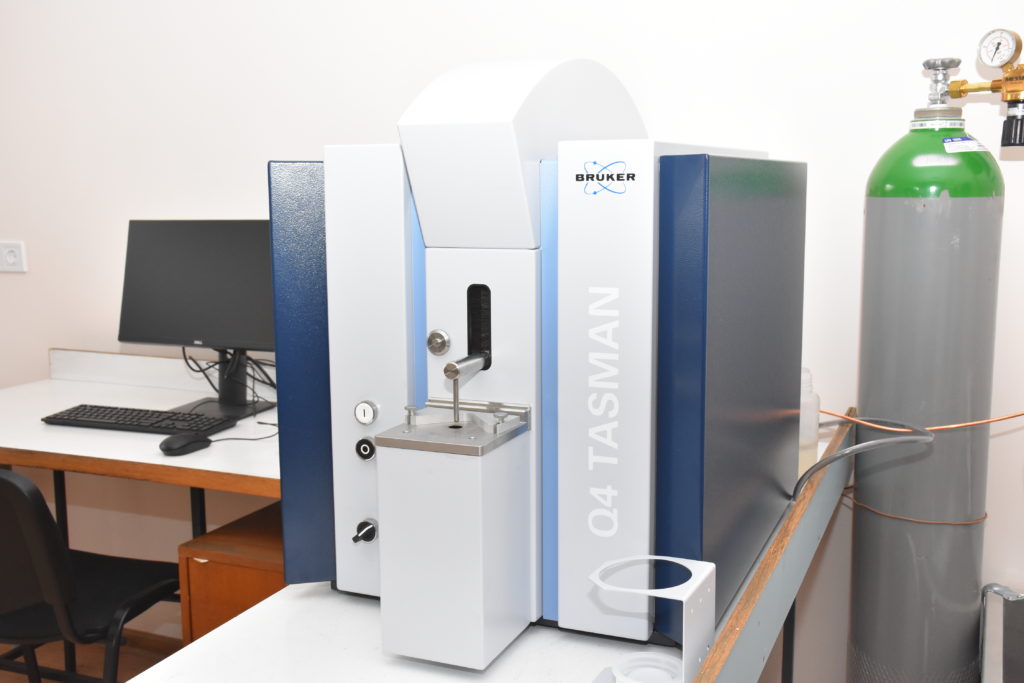

Optical emission spectrometer for metal analysis Q4 TASMAN, BRUKER

- Performs quantitative analysis of Fe, Al, Cu alloys.

- Possibility for additional upgrading for determination of Ti, Mg, Zn, Ni, Co alloys.

- Multi - CCD optics with a high resolution for wavelengths, offering precise detection of all necessary elements for the respective matrices.

- Measurement of samples of different sizes and weighing up to 10 kg. Cylindrical samples (wires and springs) with a diameter Ф 1,5 ÷ 10 mm along the length or on the forehead of the sample can be measured.

- Large database of alloy brands such as DSTM, DIN, GOST, etc. and for automatic brand recognition of the test alloy.

Scanning electron microscope HIROX 5500 with EDS microanalysis system BRUKER

The complex is designed for complex research and characterization of new metallic materials, alloys and composites at the micro and nanoscale. It consists of two modules:

- Scanning electron microscope for imaging the topography of surfaces and fractographic studies;

-

EDS system for determining the microcomposition and distribution of metallic and non-metallic phases, inclusions, defects, coatings, etc<

Features:

- Accelerating voltage up to 30 kV

- Magnification from 50 to 300,000 times

- Spatial resolution - 3 nm

- Defining elements from B to U