LABORATORY FOR THERMAL CONDUCTIVITY TESTING

Manager: Prof. D.Sc. Rumiana Kotsilkova (IMech-BAS)

e-mail: kotsilkova@imbm.bas.bg

Tel. +359 2-979-6462

The Laboratory for Thermal Conductivity testing conducts investigations on:

- Thermal conductivity of materials in a wide temperature range (-100 to 500oС), by the method of irradiation

- Tribology, lubrication studies and nanoscale surface imaging.

ACTIVITIES

The laboratory performs investigations of materials and components for application in mechatronics, electronics and other technological applications, such as:

- Complete characterization of the thermophysical properties (thermo-diffusion, thermal conductivity and specific heat capacity) of polymers, ceramics, metals and liquids;

- Study of the tribological properties (friction and wear) of different materials, polymers, films and foils; hard and superhard coatings;

- Study of the lubricating properties of oils, greases and lubricants;

- Study of the adhesion of coatings to the substrate, as well as the interlayer adhesion in multilayered electronic elements;

- Nanoscale visualization of surfaces with a Scanning Electron Microscope;

- Study of the relationship between the thermophysical characteristics of the material and the improved abrasion and wear resistance.

Potential partners and clients of the laboratory can be research teams in the country and abroad with similar scientific interests, as well as companies and manufacturers of materials, electronic components, parts for mechatronics, etc.

SERVICES

- Testing of thermal conductivity, thermal diffusion and specific heat capacity in the temperature range (-100 to 500oС) of various materials, solids and liquids in accordance with ASTM and ISO standards.

- Friction and wear tests, and determination of coefficient of friction by two standard methods, ball-on-disk and pin-on-disk, with fast reciprocating linear drive;

- Scratch test for surfaces, foils, films and coatings;

- Testing for adhesion of paints, and hard and superhard coatings to the substrate;

- Interlayer adhesion test between layers in multilayered electronics, sensors and coatings.

- Test for lubricating properties of oils and lubricants to different surfaces;

- Nanoscale visualization of surfaces with a Scanning Electron Microscope;

- Nanoscale visualization of the wear path, before and after tribological tests.

EQUIPMENT

Test equipment for thermal conductivity measurements, Laser Flash Analysis LFA467 Hyper Flash, NETZSCH:

The apparatus measures thermal diffusion, thermal conductivity and specific heat capacity of solid samples and liquids by the irradiation method in accordance with ASTM E 1461 and ISO standards. Perform fast and non-destructive analysis with high accuracy.

Characteristics:

- Temperature range: -100 to 500°C (with cooling system).

- Heating speed: up to 50 K/min.

- Measurement range:

– Thermodiffusion: 0.01 to 2000 mm2 /s.

– Thermal conductivity: 0.1 to 4000 W/mK.

Specialized modules to the existing equipment for micromechanical testing UMT-2 (Bruker):

Module for tribology (rotary type, with fast reciprocating linear drive)

The linear drive module is suitable for friction and wear testing of hard and superhard surfaces. It is characterized by an adjustable stroke from 0.1 to 25 mm and a speed from 0.1 to 25 Hz.

NEWS

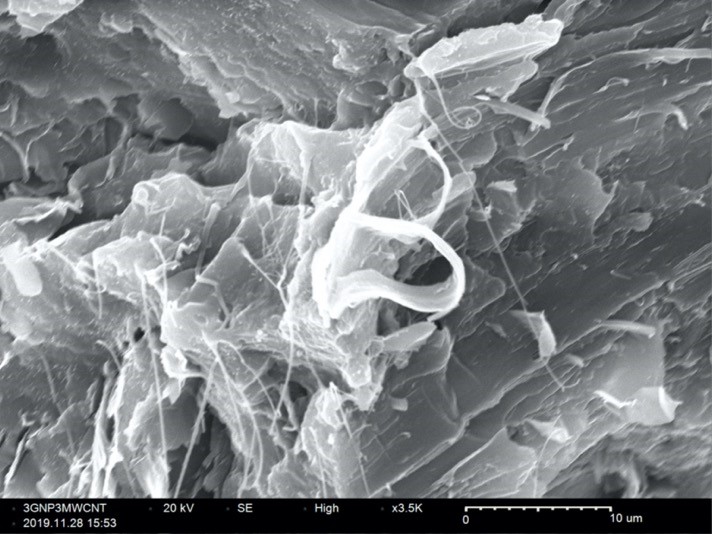

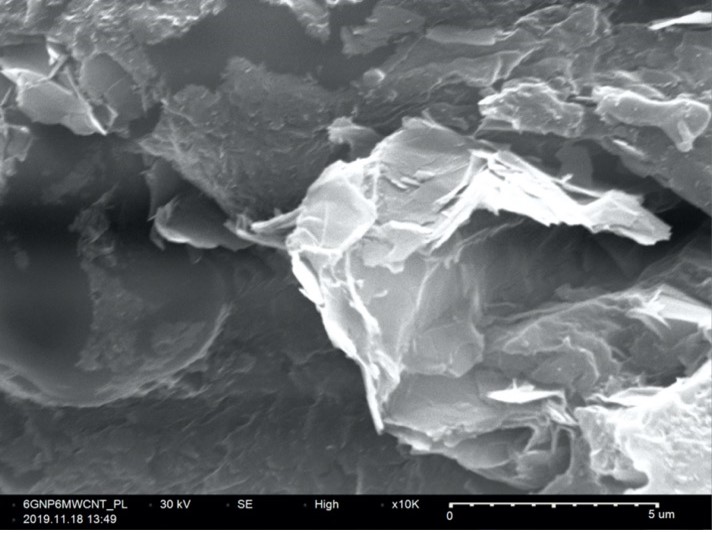

First studies are performed on the effects of graphene and carbon nanotubes to increase the thermal conductivity of nanocomposites of a biodegradable polymer, in samples and structures obtained by 3D printing.

The first results for nanoscale visualization of surfaces of polymer nanocomposites with graphene and carbon nanotubes were obtained.